Transition Update

Share

Over the last several months, you've probably noticed several changes, with some being small, some being huge, and some being somewhere in between. With a new logo and a brand spanking new website, we know a few people have probably been scratching their heads.

So, what's it all about?

In the post-COVID era, we recognized the importance of diversifying our collective skillset. And with our team, we knew we had the capability and the know-how to pull this off. We're still here serving the entertainment lighting industry, and we're not going anywhere. We're just doing a little extra now.

With over 30 years of combined manufacturing experience across our family of brands in Fort Wayne, Indiana, our expertise has lent itself well to a variety of applications. Originally starting in the entertainment lighting industry, Apollo quickly became a leader in this market. When unforeseen industry disruptions and market trends started to occur, we realized the importance of making a pivot. So, we did.

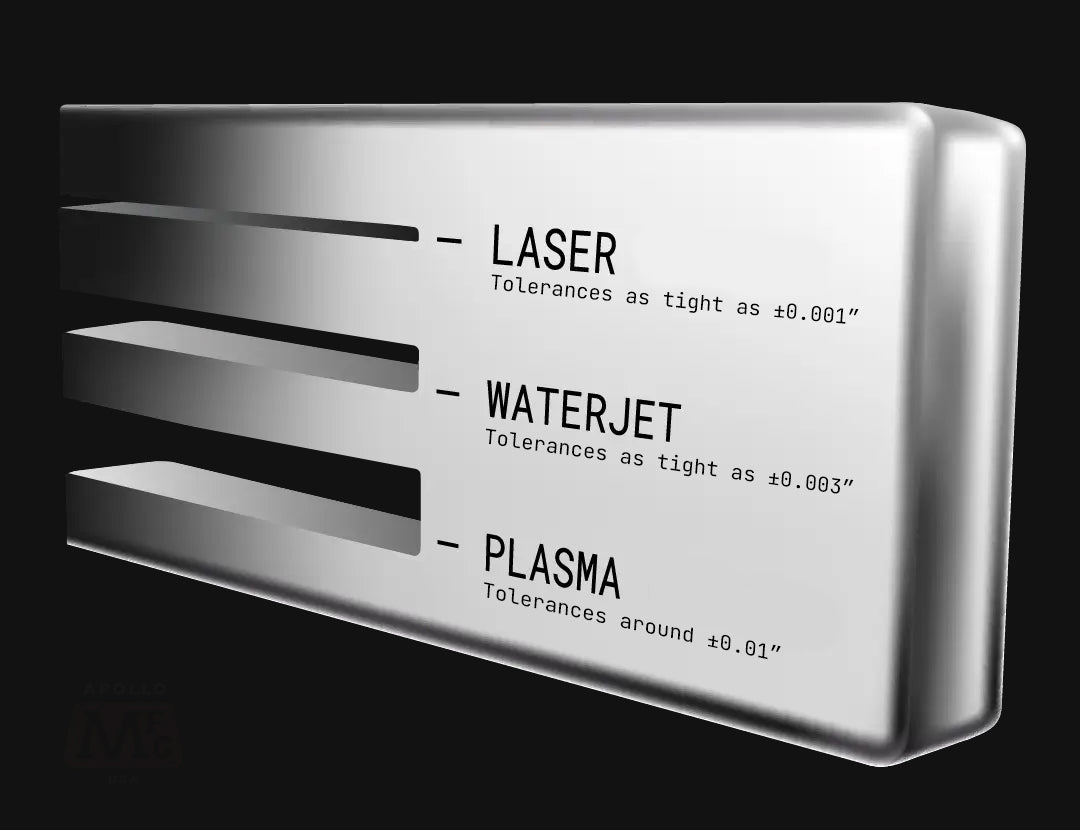

Today, our facility is making use of our fine kerf laser cutting, marking, and machine shop in new and exciting ways, however, these are not the only services we provide. Our machine shop is fully equipped with a fleet of 3D printers and is here to assist with all your prototype and fabrication needs.

Combining our engineering department, art department, machine shop, and assembly crew, we’re a one-stop shop for your industrial application and promotional product needs.

With our combined horsepower, there’s no limit on the level of creativity we can achieve.

Don't know where to start? We're here to help. Contact us today!