Metalworking Techniques: An Overview

Share

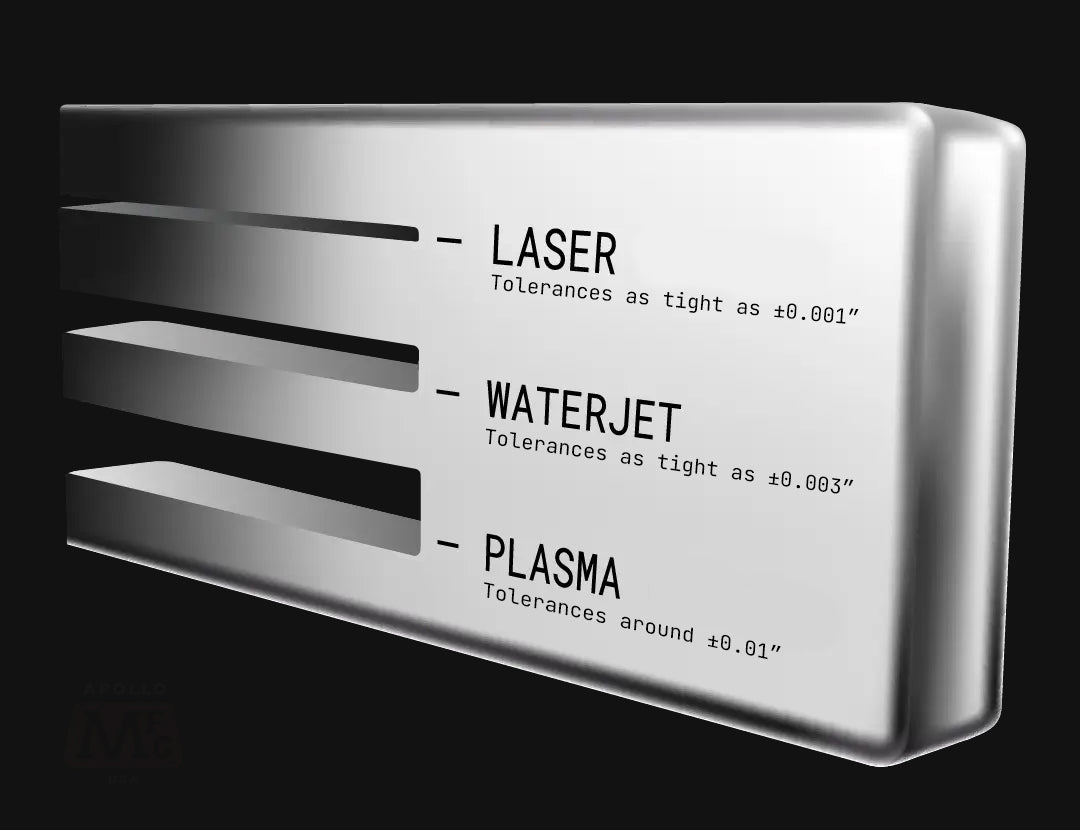

When it comes to cutting material, getting the right process for the job is crucial. So what is the best fit for you? It really depends on the end result you're trying to achieve, and today we break down a number of different methods that can be deployed.

Chemical Etching

Chemical etching, also known as chemical milling or photochemical machining, involves using a chemical solution to selectively remove material from a workpiece. The process starts with cleaning the material to remove any contaminants. A photoresist, which is a light-sensitive material, is then applied to the surface. Using UV light, a mask with the desired pattern is projected onto the photoresist, which is subsequently developed to reveal the pattern. The exposed areas are then subjected to an etchant, a chemical solution that dissolves the metal, while the protected areas remain intact. This method is precise and is often used for creating intricate designs on metals, circuit boards, and other materials.

Waterjet Cutting

Waterjet cutting employs a high-pressure jet of water, often mixed with an abrasive substance, to cut through various materials. The process begins by pumping water at extremely high pressures, sometimes up to 90,000 psi, through a small nozzle to form a concentrated jet. When an abrasive is added, such as garnet, the cutting power is significantly enhanced, allowing the waterjet to slice through hard materials like metal, stone, and ceramics. The waterjet is guided by a computer-controlled system, ensuring precise and intricate cuts. This method is advantageous because it does not generate heat, preventing thermal distortion or changes in the material properties.

Laser Etching

Laser etching, or laser engraving, uses a high-powered laser beam to remove material from the surface of an object, creating a visible mark. The process begins with a computer-aided design (CAD) of the pattern to be etched. This design is fed into a laser machine that focuses the laser beam on the workpiece. As the laser moves according to the design, it vaporizes the material, leaving behind a permanent mark. The depth and contrast of the etching can be controlled by adjusting the laser's power, speed, and frequency. Laser etching is precise and can be used on a variety of materials, including metals, plastics, glass, and wood, making it ideal for detailed designs and serial number markings.