Knife Making and Laser Cutting: A Perfect, Precise Match

Share

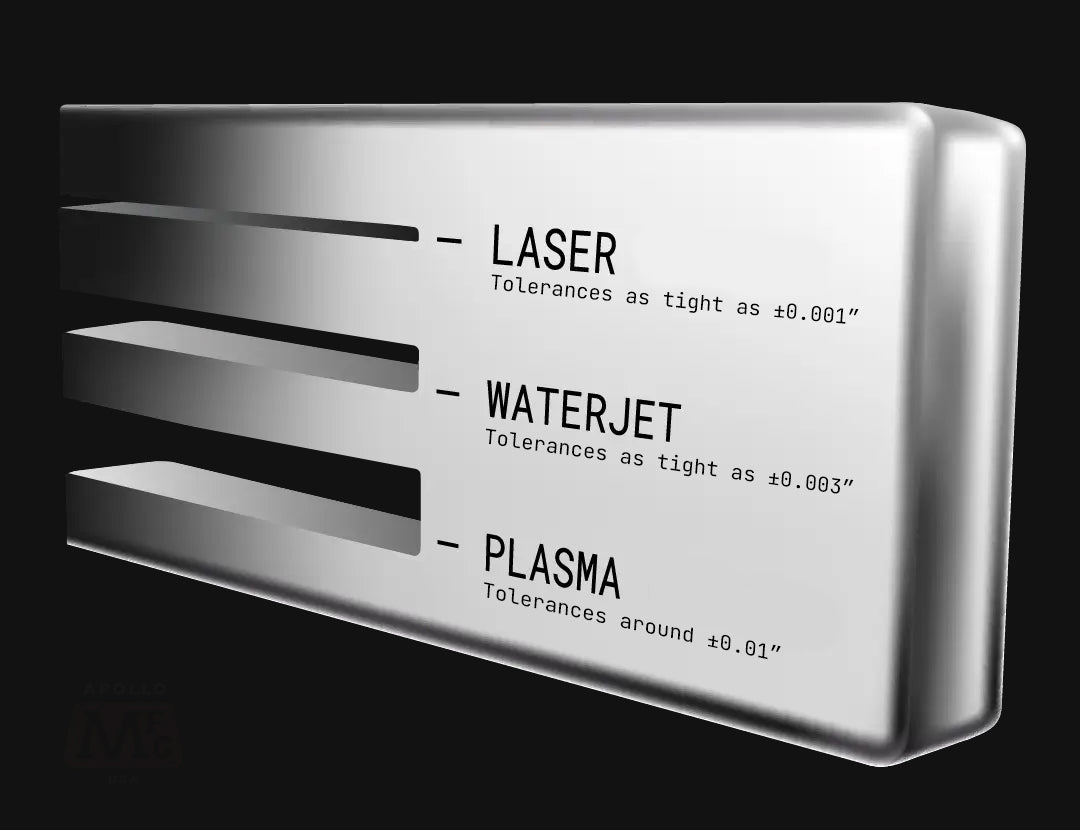

Laser cutting is a versatile fabrication method used in the creation of knives, allowing for precision and efficiency in shaping various components. One of the primary parts that can be laser cut is the blade itself. High-quality steel sheets, such as stainless steel, carbon steel, or tool steel, can be cut into the desired blade shape with extreme accuracy. At Apollo MFG, our laser cutting process ensures smooth edges and intricate designs, including serrations or decorative patterns. This method also reduces waste and improves uniformity in production, making it ideal for both custom knife makers and mass manufacturers.

Laser cutting is a versatile fabrication method used in the creation of knives, allowing for precision and efficiency in shaping various components. One of the primary parts that can be laser cut is the blade itself. High-quality steel sheets, such as stainless steel, carbon steel, or tool steel, can be cut into the desired blade shape with extreme accuracy. At Apollo MFG, our laser cutting process ensures smooth edges and intricate designs, including serrations or decorative patterns. This method also reduces waste and improves uniformity in production, making it ideal for both custom knife makers and mass manufacturers.

Another critical component that benefits from laser cutting is the handle itself. Handles are often made from a variety of materials such as wood, acrylic, aluminum, or composite materials like G10 or Micarta. Laser cutting enables these materials to be shaped into ergonomic forms that fit seamlessly with the blade tang. Additionally, the process can be used to engrave logos, text, or decorative motifs on the handle, adding aesthetic value and branding.

Have an idea you’d love to see come to life? Our art department can help you design exactly what you want. Best of all, the precision of laser cutting ensures that even intricate inlays or cutouts are executed without error for a stunning result.

Our laser cutting services can also be employed to create auxiliary components, such as spacers, liners, and sheaths. Spacers and liners, typically made from thin sheets of metal or synthetic materials, are used to add structural integrity and enhance the knife's appearance. Laser cutting these components ensures they align perfectly with the blade and handle. This process not only enhances the functionality of the knife but also contributes to its overall presentation and durability.

Why Apollo MFG?

Why Apollo MFG?

From knife blanks to liners, sliders, and scales, our laser can handle a variety of materials, offering maximum flexibility for your projects. With a minimal heat-affected zone, Our laser ensures precision all while preserving the overall integrity of the material.

When precision counts, Apollo MFG is ready to help. Contact us today to get started.