High-Precision Laser Cutting with Cost-Efficient Power for High-Carbon Steel

Share

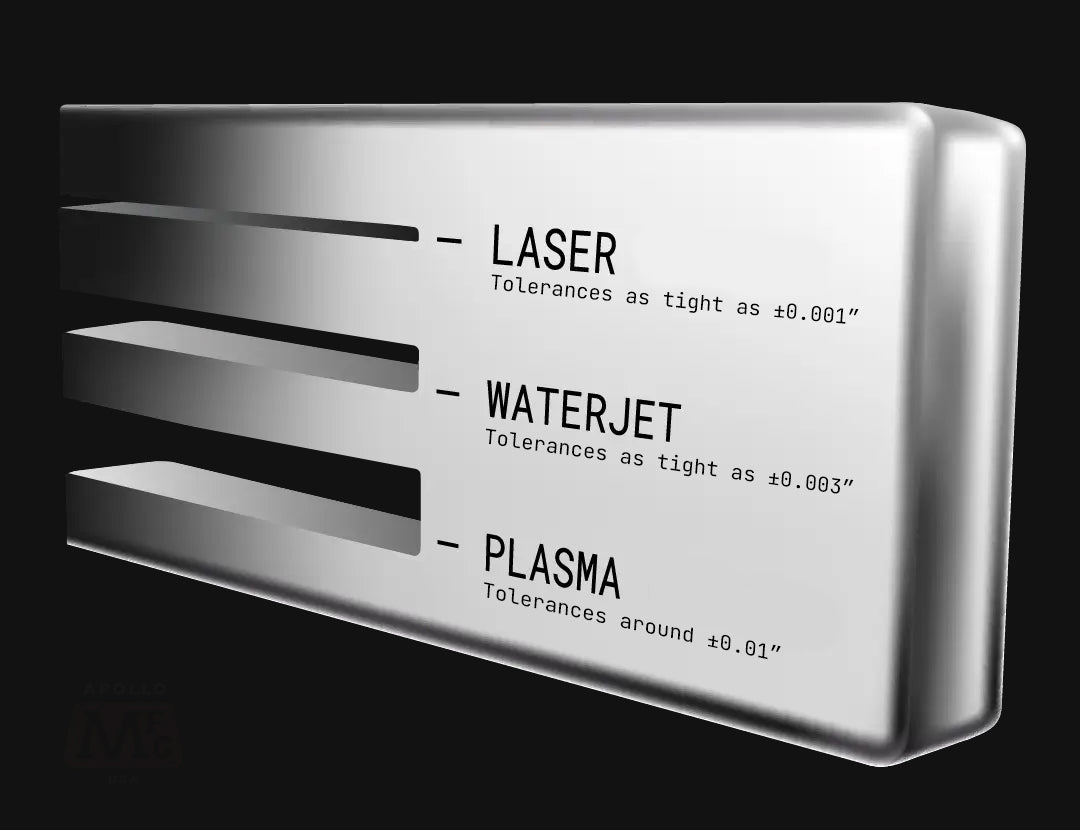

Laser and thin metal cutting has revolutionized precision manufacturing by offering repeatable, high-accuracy results, especially for challenging materials like high-carbon steel. We want to explore the process behind this efficiency, focusing on how our cutting-edge techniques keep costs low while achieving top-quality results.

Key Benefits of Our Laser Cutting Process

-

Repeatable, High-Accuracy Cutting

- Our laser systems are designed to produce consistently precise cuts on high-carbon steel, even in intricate patterns or fine details.

- This precision is crucial for applications that demand exact specifications, ensuring each piece meets the highest quality standards.

-

Use of 100 PSI Oxygen to Minimize Dross/Burr

- By incorporating 100 psi of oxygen during the cutting process, we significantly reduce the formation of dross and burr, the rough or raised edges often seen after cutting.

- This method results in cleaner edges and reduces the need for additional finishing work, saving both time and cost in the production cycle.

-

Quick Travel Speeds for Efficient Processing

- Our laser cutters operate at rapid travel speeds, which means we can cut high-carbon steel (at a thickness of just .010 inches) faster and more efficiently than traditional methods.

- This speed is especially beneficial for large production runs, where minimizing time per piece without compromising quality is essential.

-

Affordable 1kW Power Usage

- Unlike some high-energy-consuming laser systems, our process uses a more affordable 1kW of power, making it a sustainable and cost-effective solution.

- This efficient power usage also allows us to provide quality laser cutting at competitive rates without sacrificing quality.

At Apollo MFG, we are committed to combining high-tech precision with cost-effective solutions for our customers. Our laser services reflect this commitment by delivering outstanding accuracy, efficiency, and affordability.