Exploring CNC Equipment

Share

CNC is an acronym used often, but for those outside the industry, they may not know what CNC is or what the equipment is used for. CNC (Computer Numerical Control) equipment encompasses a range of machines used for precision manufacturing processes.

One common piece of CNC equipment is the CNC milling machine. These machines use rotating cutting tools to remove material from a workpiece, resulting in precise and intricate shapes and designs. Top-rated CNC milling machines often feature high spindle speeds, multi-axis capabilities, and efficient control systems, allowing for versatile and high-quality machining operations across various industries.

Another common piece of CNC equipment is the CNC lathe. Lathes are best known for their ability to produce cylindrical or round-shaped parts with outstanding precision. These machines can perform operations such as turning, facing, threading, and grooving on a workpiece. Most of the top-rated lathes in the industry often boast features such as high spindle speeds, rigid structures, automatic tool changers, and advanced control systems, enabling efficient and accurate machining of complex geometries.

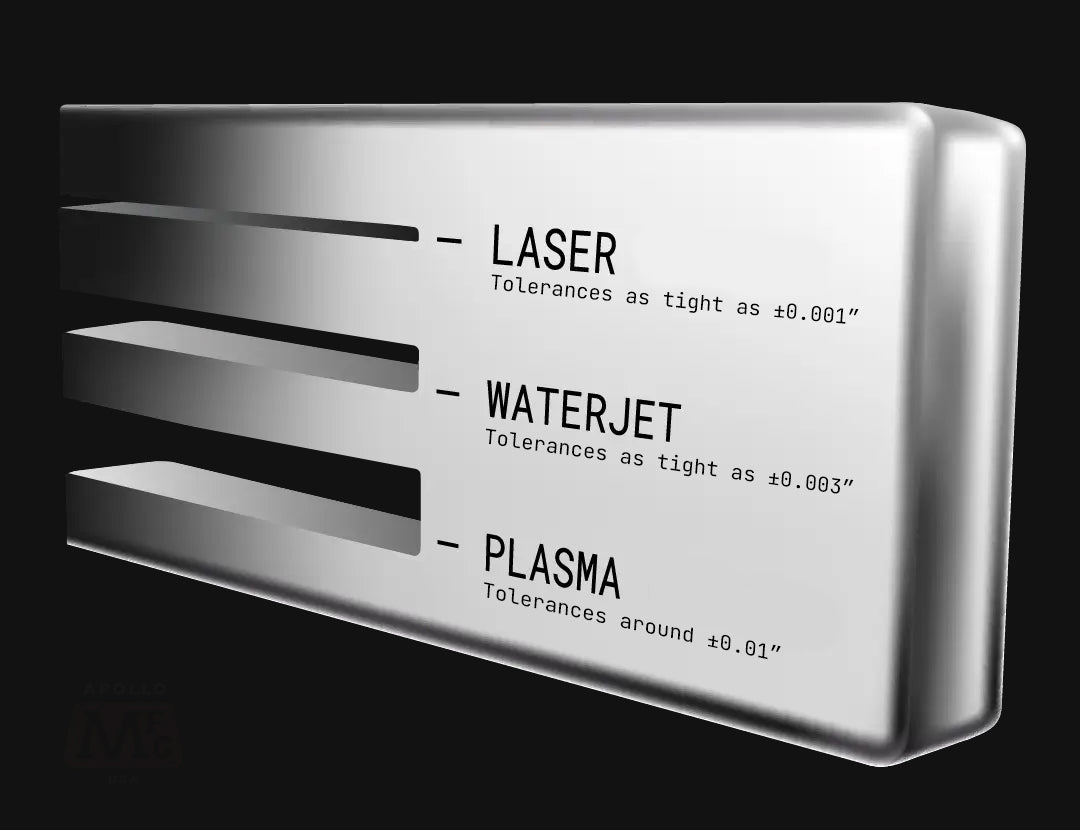

Last but certainly not least, CNC laser cutting machines are one of the biggest heavy hitters in the CNC realm. These machines utilize focused laser beams to cut through various materials with exceptional precision and speed. They can process a wide range of materials, including metal, wood, plastic, and composites. With high-powered lasers, automated material handling systems, and precise control mechanisms, these machines ensure clean, precise, and efficient cutting operations. Simply put, these machines are indispensable tools in the automotive, aerospace, and signage industries, and are essential for achieving optimal results in modern manufacturing.